Welds are designed to meet a multitude of performance requirements including, but not limited to:

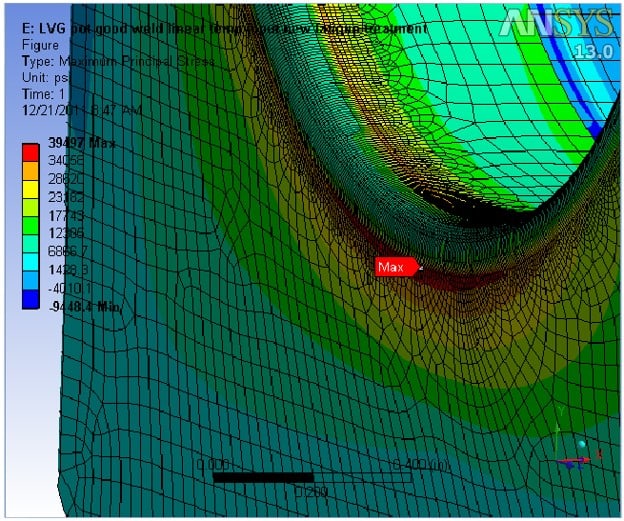

• Strength (tension, compression, torsion, bending)

• Corrosion resistance

• Vibration

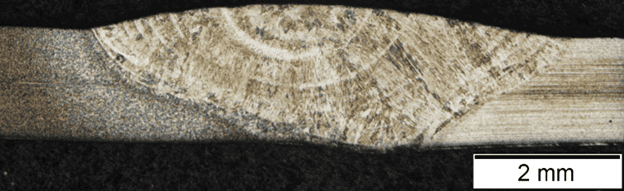

• Fatigue (mechanical, thermal)

• Toughness

• Creep

• Electrical and thermal conductivity

• Appearance

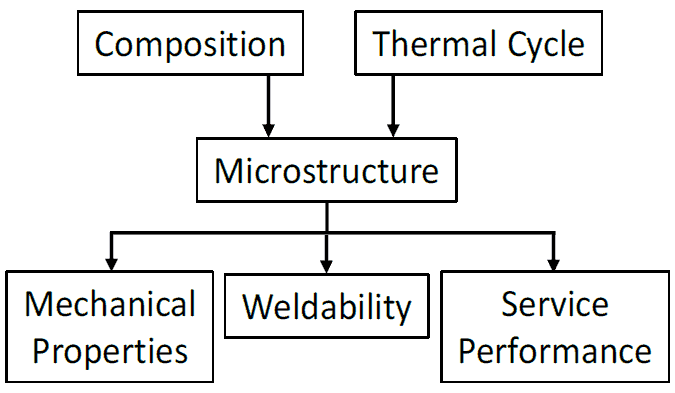

The functional results of any given weld are dependent on:

• Joint design

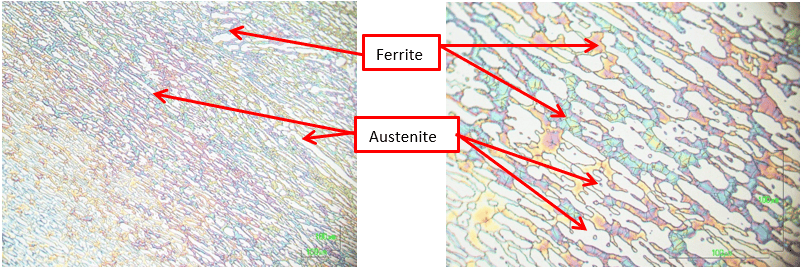

• Material selection

• Process selection

All three elements in the list above affect each other. In addition, both the performance requirements and functional results must be taken into consideration during the design of any new product or component which includes welded elements.

Weld design engineers must also ensure that their welding solutions comply with constantly evolving industry standards and codes. This includes:

• Staying up-to-date with relevant regulations and guidelines

• Conducting quality control checks to ensure that the welding solution meets the required standards and specifications

Our engineers work hard to track and learn about industry developments. They also collaborate with other professionals to develop and test new welding solutions that:

• Improve efficiency

• Reduce costs

• Enhance safety

• Joint design

• Material selection

• Process selection

• Testing

• Post weld heat treatments

• Functional requirements

• Quality, codes and standards

Based in Cleveland, Ohio

Fusing ideas with reality.