Ensuring compliance to welding and brazing industry codes, specifications and standards can be a burdensome process. Users often:

Moreover, some customers have their own specifications that are intended to address specific requirements and may supersede and/or reference these codes. Understanding how to use and apply these documents is critical for meeting end user and purchaser contractual agreements.

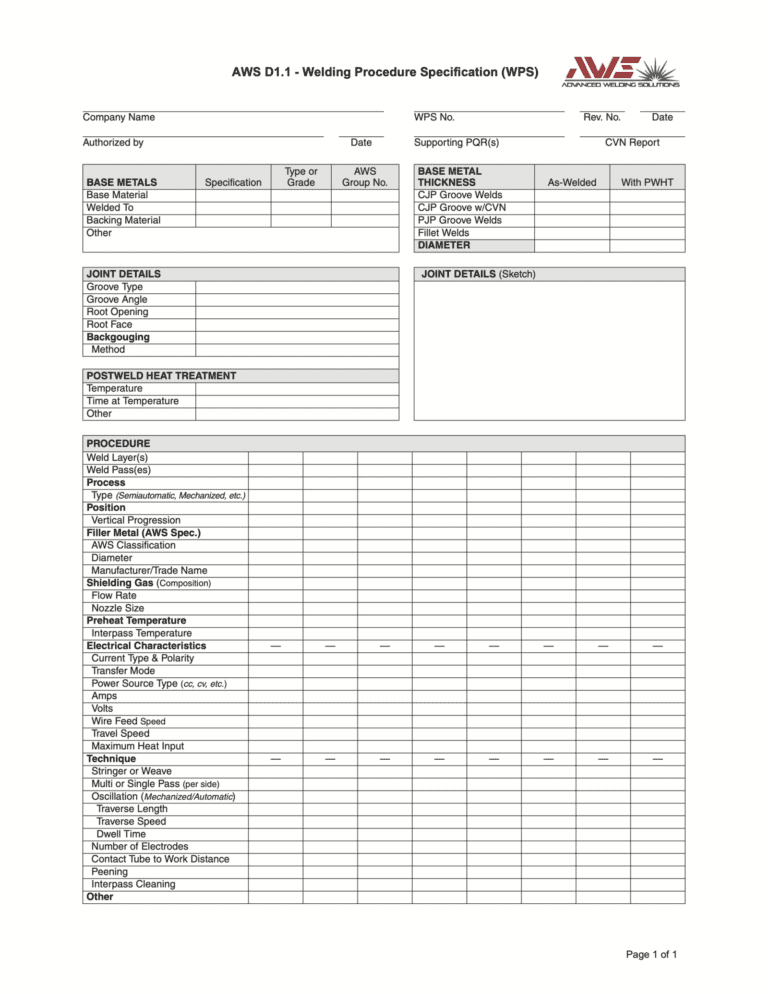

There are three main types of weld documentation:

• Procedure Qualification Records, PQRs

• Welding Procedure Specifications, WPSs

• Welder Performance Qualifications, WPQs

These are interconnected elements in the realm of welding that collectively ensure the integrity and competency of the welding process.

Adhering to established WPSs ensures consistent and repeatable weld quality, meeting the specified criteria for strength, integrity, and dimensional accuracy.

The interplay between PQRs, WPSs, and WPQs is crucial for maintaining welding quality and compliance. Proper qualification of procedures through PQRs and the establishment of accurate WPSs provide a standardized framework for welders to follow. Welder performance qualifications ensure that individuals possess the necessary skills and knowledge to execute the welding procedures correctly.

Together, these elements form a comprehensive system that instills confidence in the welding process, enabling organizations to consistently produce high-quality welds and meet industry standards. By emphasizing the importance of PQRs, WPSs, and WPQs, organizations can enhance the:

Organizations that become compliant by developing the proper welding documentation, procedures, and processes enjoy benefits including:

Companies attempting to certify an organization to a quality management system (i.e. ISO 9000 family) will see process control requirements as part of that certification process. Each organization will have to show proof of:

AWS’ mission is “Advancing the science, technology, and application of welding and allied joining and cutting processes, including brazing, soldering and thermal spraying.” AWS has published several hundred welding specifications, standards and documents. All AWS standards are approved by the American National Standards Institute (ANSI). A few common AWS publications:

• AWS B2.1 – Specification for Welding Procedure and Performance Qualification

• AWS B2.2 – Specification for Brazing Procedure and Performance Qualification

• AWS D1.1 – Structural Welding Code (Steel)

• AWS D1.2 – Structural Welding Code (Aluminum)

• AWS D1.3 – Structural Welding Code – Sheet Steel

• AWS D1.4 – Structural Welding Code – Reinforcing Steel

• AWS D1.5 – Bridge Welding Code

• AWS D1.6 – Structural Welding Code – Stainless Steel

• AWS D9.1 – Sheet Metal Welding Code

• AWS D14.3 – Specification for Welding Earthmoving, Construction, Agricultural, and Ground-Based Material Handling Equipment

• AWS D17.1 – Specification for Fusion Welding for Aerospace Applications

ASME publishes the Boiler and Pressure Vessel Code (BPVC) and the Code for Pressure Piping, both of which contain information regarding design, construction, and inspection of boilers and pressure vessels. Common ASME publications:

• ASME BPVC Section I – Rules for Construction of Power Boilers

• ASME BVPC Section III – Rules for Construction of Nuclear Facility Components

• ASME BVPC Section VIII – Rules for Construction of Pressure Vessels

• ASME BVPC Section IX – Welding, Brazing & Fusing Qualifications

• ASME B31.1 – Power Piping

• ASME B31.3 – Process Piping

• ASME B31.4 – Pipeline Transportation Systems for Liquids and Slurries

• ASME B31.8 – Gas Transmission & Distribution Piping Systems

• ASME B31.9 – Building Services Piping

API establishes and maintains standards for the oil and natural gas industry worldwide. This institute has published 700+ standards relating to petroleum production.

• API 1104 – Standard for Welding Pipelines and Related Facilities.

NAVSEA is the primary technical authority for the design, construction, maintenance, and operation of U.S. Navy ships and submarines. NAVSEA has developed several welding codes that are specific to the needs of the Navy.

• NAVSEA S9074-AQ-GIB-010/248 (MIL-STD-248) – Requirements for Welding and Brazing Procedure and Performance Qualification

• NAVSEA S9074-AR-GIB-010/278 (MIL-STD-278) – Requirements for Fabrication, Welding and Inspection, and Casting Inspection and Repair for Machinery, Piping, and Pressure Vessels

• NAVSEA T9074-AS-GIB-010/271 (MIL-STD-271) – Requirements for Nondestructive Testing Methods

ISO is an independent, non-governmental organization that develops and publishes international standards for various industries, including welding.

● ISO 15614 – Specification and Qualification of Welding Procedures for Metallic Materials – General Rules

● ISO 9606 – Qualification Testing of Welders – Fusion Welding

Based in Cleveland, Ohio

Fusing ideas with reality.