When running a fabrication business, every dollar counts. If you’re not careful, profits will be lost because the welding process is not optimized to achieve the highest quality and lowest cost. For many companies, when sparks and smoke are present, the welder is productive and efficient in management’s eyes. Advanced Welding Solutions works with companies to determine actual welding costs and improve efficiency by reviewing your processes, equipment, consumables, and welder capability.

Our goal is to improve your efficiency and profit margins by reducing:

• Weld metal volume

• Arc time per weldment

• Rejects, rework and scrap

• Work effort

• Motion and delay time

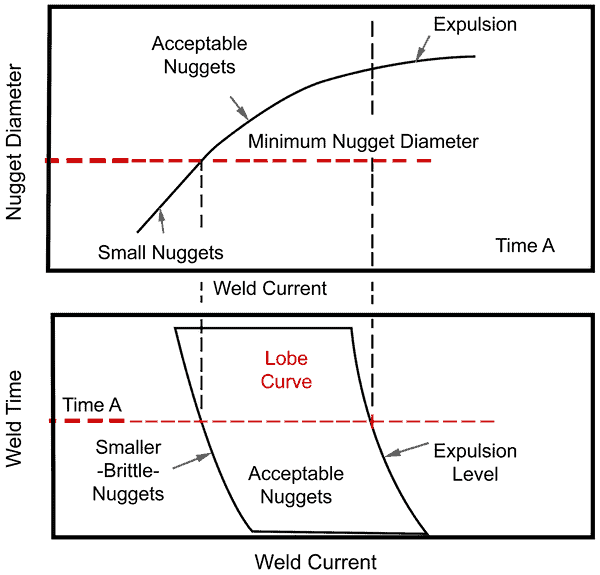

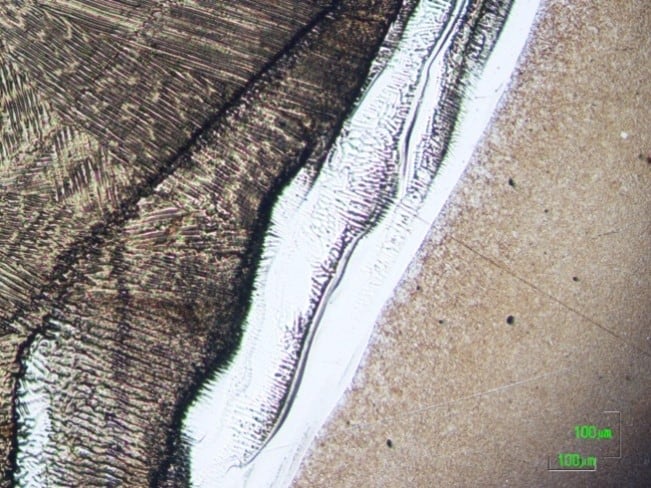

Advanced Welding Solutions’ program for working with manufacturers identifies specific areas for weld quality improvement and cost reduction. Below are just a few common factors impacting profits:

Based in Cleveland, Ohio

Fusing ideas with reality.