In today’s industrial landscape, where precision and efficiency are essential, weld training is your ticket to immediate ROI. Yet, it’s surprising how many companies entrust their operations—and futures—to the hands of untrained professionals. Advanced Welding Solutions is addressing this critical skills gap with customized, in-depth training programs designed to improve both the quality of welding and the safety practices within your organization.

The High Cost of Poor Welding Skills

Many organizations are unaware of the potential risks and financial losses stemming from inadequate weld training. The reality is stark: billions of dollars are lost annually due to poor welding practices that stem from a fundamental lack of understanding of welding processes. This is not just about the immediate costs of rework or failure, but also about the long-term reputational damage that can cripple a company.

Tailored Training: The Advanced Welding Solutions Edge

Advanced Welding Solutions offers customized employee training designed to fit the specific needs of your organization. Whether it’s basic metal joining processes or more advanced techniques like laser beam welding and electron beam welding, we provide comprehensive training that covers all necessary aspects, including areas like:

- Metal properties and destructive testing

- Weld and base metal discontinuities

- Visual inspection and other non-destructive examination methods

- Safe practices to mitigate common welding hazards

For a full list of training courses available through AWS, visit our Weld Training page.

Ohio-Based Weld Training

Are you an Ohio-based company? You may qualify for free or reduced-cost training through the Ohio TechCred program. Learn more about the Ohio TechCred courses we offer here.

Real-World Applications and Impact

Training with Advanced Welding Solutions goes beyond theory. It ensures that your staff can apply their new skills directly to their job functions, leading to an immediate return on investment. Imagine a workforce that not only understands the “how” but also the “why” behind each weld they make. This level of proficiency can dramatically reduce the incidence of welding defects, improve overall product quality, and decrease liability for your company.

Essential Knowledge for Modern Welding Challenges

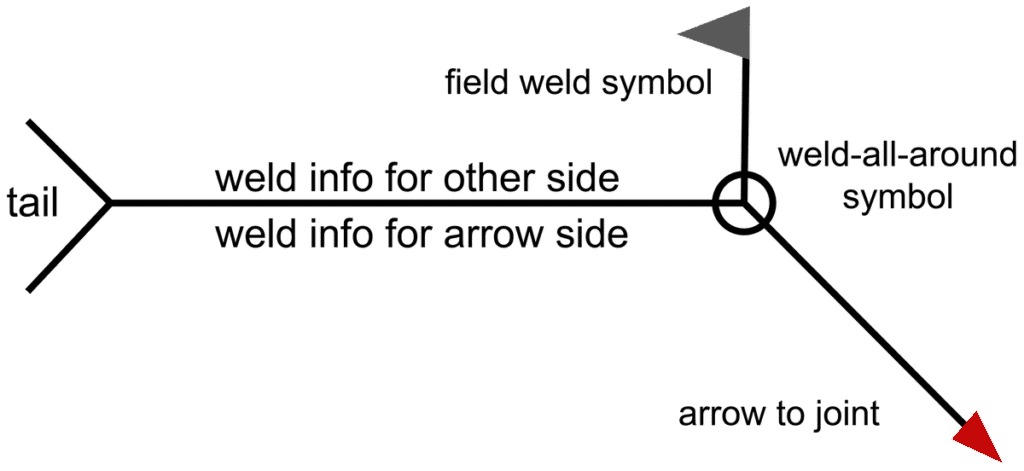

When you work with us, we will also delve into crucial aspects of the industry like weld joint geometry and welding symbols, documents governing welding inspection and qualification, and the intricate details of welding metallurgy. Such knowledge is indispensable in today’s complex fabrication environments where precision and adherence to standards are paramount. We can even help you develop your own Weld Quality Manuals to ensure code compliance.

Equip Your Welding Team and See the Difference

Our commitment to fusing ideas with reality is not just a tagline, but a promise. By embracing specialized weld training, you will not only see a significant reduction in weld-related issues but can also enhance your operational efficiency and product reliability. This is the kind of investment in skills that pays dividends far beyond the cost of training, safeguarding both your company’s present operations and its future reputation. Equip your team with the knowledge and skills they need to excel in the demanding world of modern welding.

For more information or to schedule a training session, contact us today.