Weld Procedure Development and Welder Performance Qualification are essential for maintaining compliance with welding and brazing industry codes, specifications, and standards. These processes often present challenges, such as navigating through complex documents and understanding technical language, especially for those new to welding and brazing. Moreover, specific customer requirements may necessitate adherence to unique specifications that reference or even supersede standard codes.

Why is Code Compliance Important?

Code compliance is vital for a company’s reputation and operational efficiency. It governs the design and fabrication of welded and brazed components, ensuring products play a safe role in public health and safety. These codes and standards are mandatory in sectors like aerospace, power generation, construction, and oil and gas, and have been adopted internationally, sometimes becoming laws.

Benefits of Code Compliance

Compliance not only enhances the reliability and performance of welded structures but also significantly reduces costs associated with rework, scrap, and labor. Furthermore, it reduces the risk of weld failure, which can lead to costly repairs, downtime, and potential injuries or loss of life.

Understanding Weld Documentation

There are three main types of weld documentation:

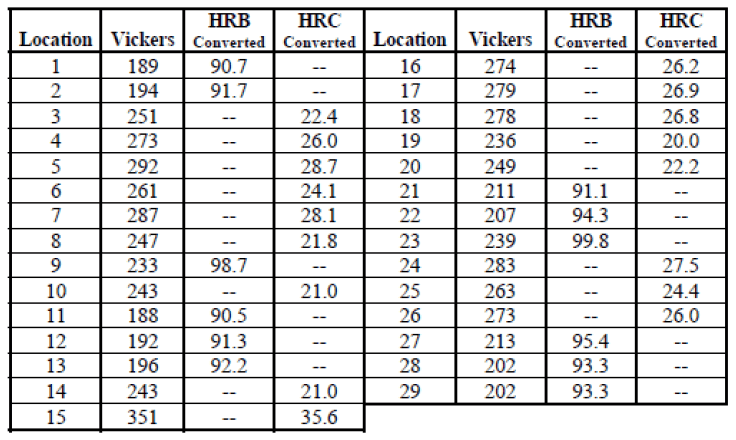

- Procedure Qualification Records, PQRs

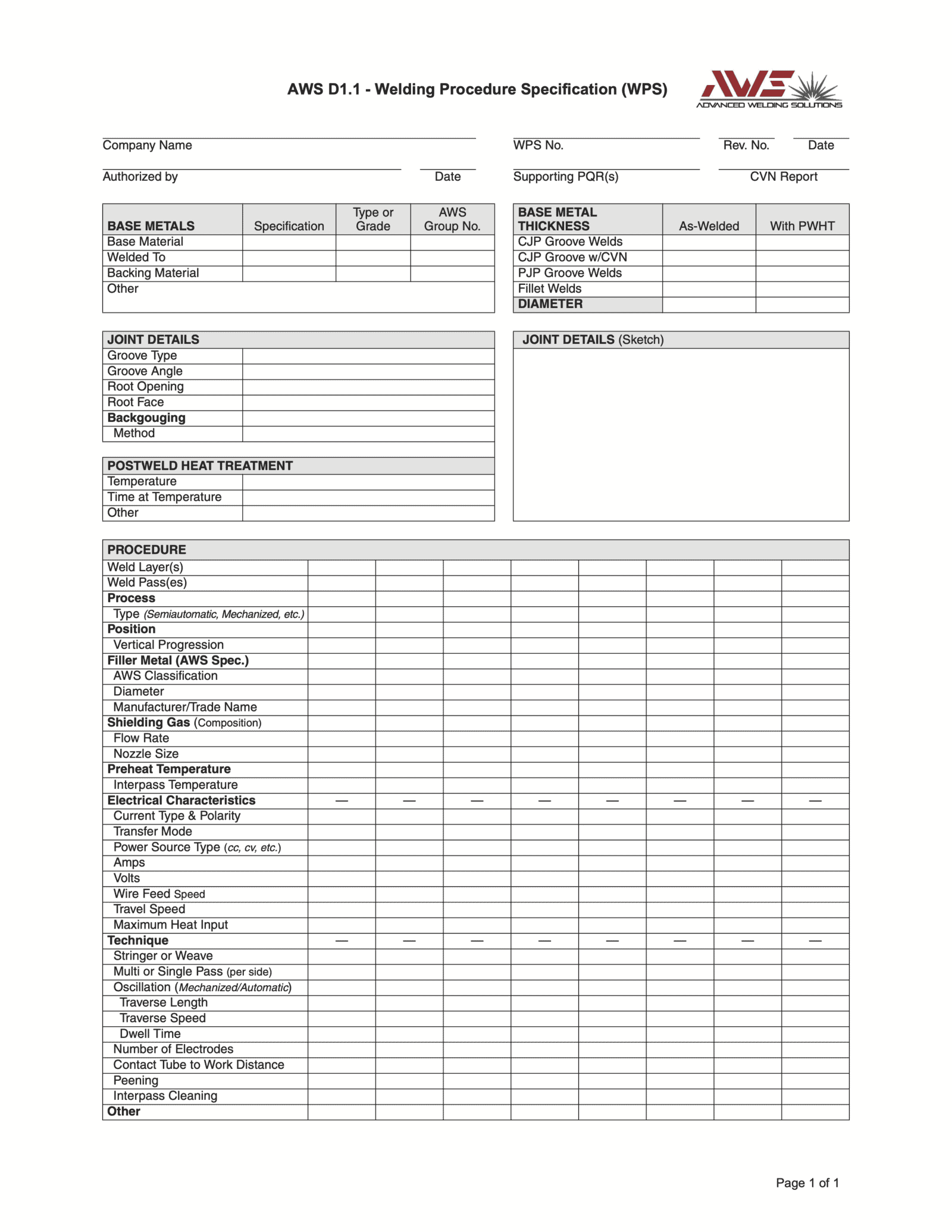

- Welding Procedure Specifications, WPSs

- Welder Performance Qualifications, WPQs

Together, they ensure the integrity and competency of the welding process.

Procedure Qualification Records (PQRs)

PQRs document the testing of welding parameters, demonstrating their capability to produce reliable welds and form the basis for developing WPSs.

Welding Procedure Specifications (WPSs)

WPSs provide detailed guidelines for production welding, covering aspects from materials and joint design to welding parameters and post-weld heat treatment.

Welder Performance Qualifications (WPQs)

WPQs assess and validate a welder’s ability to perform according to specified procedures and quality standards.

When combined, this comprehensive documentation ensures that every aspect of the welding process is standardized, repeatable, and up to code, thus guaranteeing the production of high-quality welds.

Working with Advanced Welding Solutions to Ensure Welding Code Compliance

Advanced Welding Solutions offers expertise in qualifying welding procedures to any welding code or standard and can assist in reviewing existing procedures for compliance or work with you to develop procedures. We help you recognize and adhere to commonly used welding codes such as those from the:

- American Welding Society (AWS)

- American Society of Mechanical Engineers (ASME)

- American Petroleum Institute (API)

- Naval Sea Systems Command (NAVSEA)

- International Organization for Standardization (ISO)

- Others…

Are you ready to review and improve your code compliance? Contact us today to start the process.